Contents

1. Preface – Understanding Modular Power Converters

2. Miniaturization – Save System Space

3. Easy Power Upgrade with Modular Power Converters

4. Isolated DC-DC Converters Optimize Electrical and Thermal Performance

5. Optimization of Thermal Design of Isolated DC-DC Converters

6. Our Modular Power Converters are Designed for Harsh Environments

Preface – Understanding Modular Power Converters

Whether to use discrete or modular power converters is a common issue for engineers. The primary concerns are typically PCB space constraints and the power density of the converter. These requirements can significantly impact cost.

Today, most companies lack the resources or dedicated teams to develop custom power converters. Instead, engineers often rely on existing modular power converters to meet application needs quickly and effectively. This shift emphasizes the importance of solving complex power challenges within limited resources and timeframes.

With the rising demand for compact and high-performance solutions, modular power converters have become the preferred choice. Although modular power supplies may appear more expensive than discrete solutions at first glance, their benefits—such as ease of use, reliability, and scalability—often outweigh the costs.

MINMAX specializes in modular power converters, offering over 30 years of expertise in isolated DC-DC and AC-DC converters. Our range spans 1W to 150W for DC-DC converters and 3W to 60W for AC-DC converters, designed to meet diverse application needs.

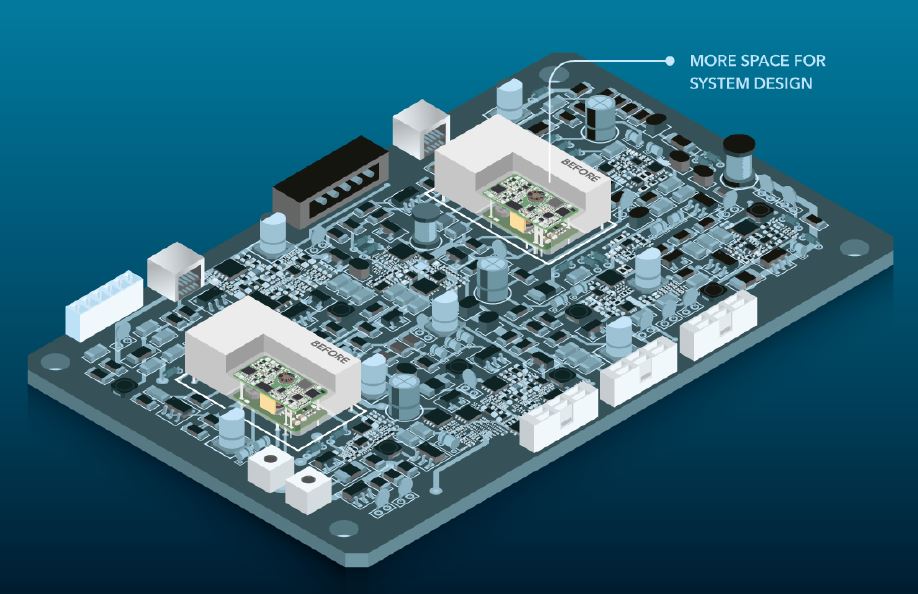

Miniaturization – Save System Space

MINMAX prioritizes miniaturization in its isolated DC-DC converter designs, leveraging high-performance components and advanced integration techniques.Our research has achieved:

● Up to 75% reduction in product size without compromising output power.

● Increased power density to 150W/in³.

For customers with limited PCB space, MINMAX’s solutions of modular power converters are the optimal choice.

Figure 1- Adopting modular power supply can significantly save design space in the system

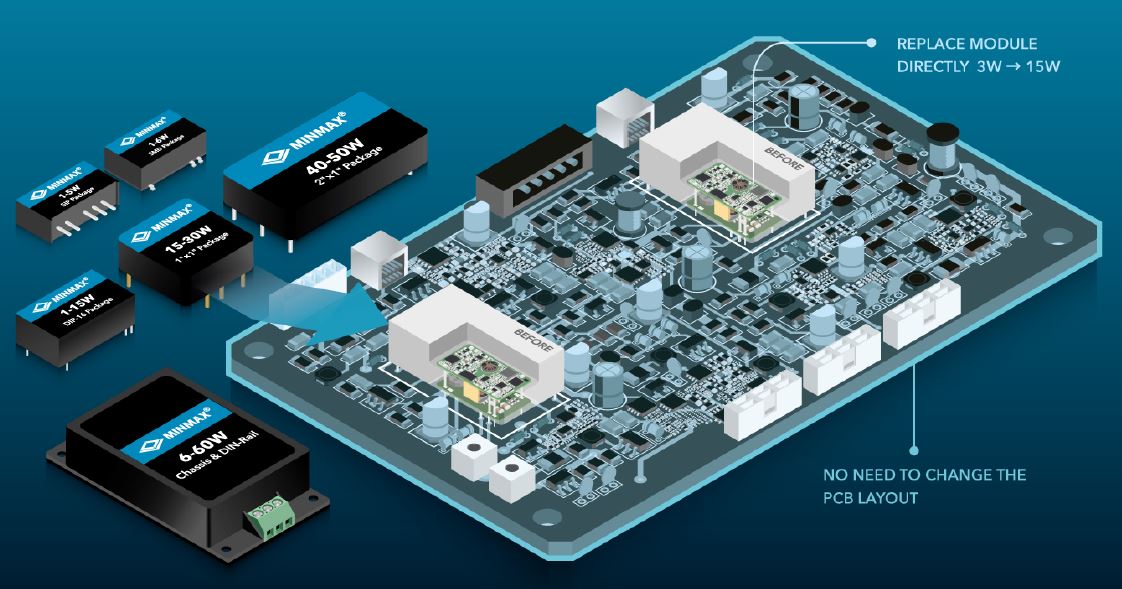

Easy Power Upgrade with Modular Power Converters

MINMAX’s modular power converters follow industry-standard form factors, making them easy to integrate and upgrade. Replacing an existing module with one offering different power outputs is seamless and requires no rewiring. This flexibility ensures faster deployment and adaptability to evolving system requirements.

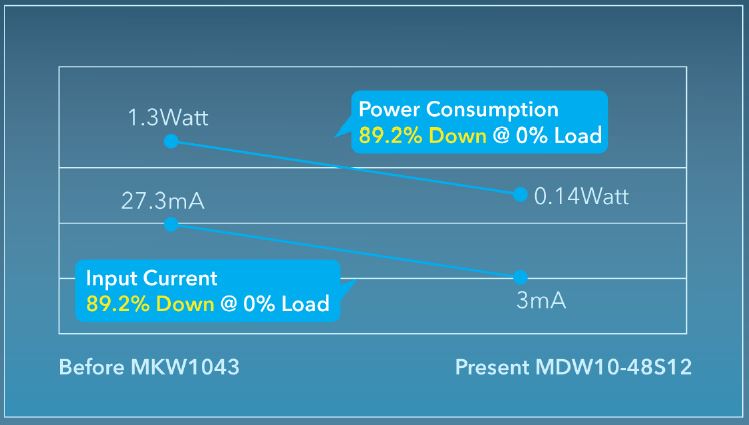

Isolated DC-DC Converters Optimize Electrical and Thermal Performance

To simplify design complexities, MINMAX incorporates advanced technologies such as:

- Active clamping and synchronous rectification.

- Energy-saving circuitry for low ripple, noise, and power consumption.

Our modular power converters are engineered to handle dynamic conditions such as fluctuating loads and extreme temperatures, delivering consistently optimized performance.

Figure 3- The power module designed by MINMAX can provide overall optimized electrical performance

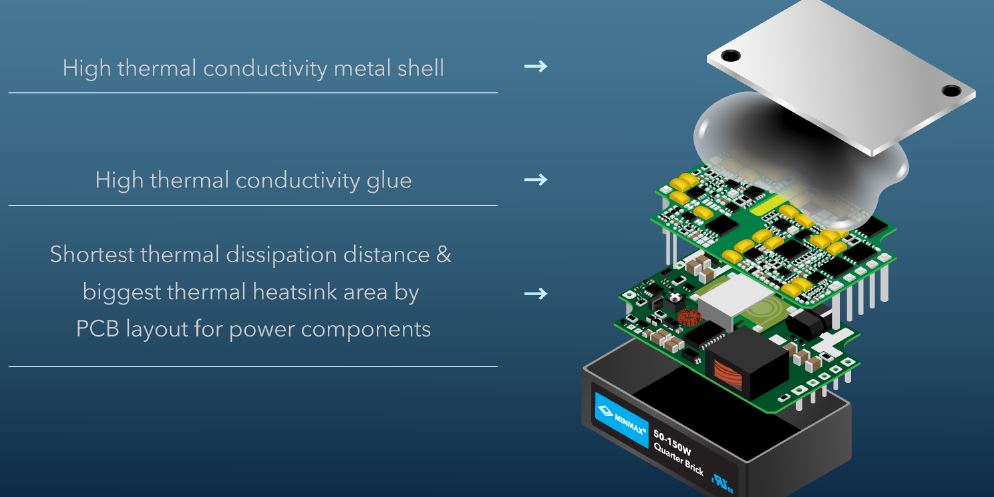

Optimization of Thermal Design of Isolated DC-DC Converters

The Isolated DC-DC Converters of MINMAX uses high thermal conductivity adhesive and high thermal conductivity metal shell in raw materials, coupled with advanced electronic circuit design and optimized circuit board distribution design, which can quickly transfer thermal energy during operation, improve overall power module efficiency and thermal performance, and provide the best solution for customers considering harsh working environments.

Figure 4- Optimized thermal structure design can improve overall power module efficiency and thermal performance

Our Modular Power Converters are Designed for Harsh Environments

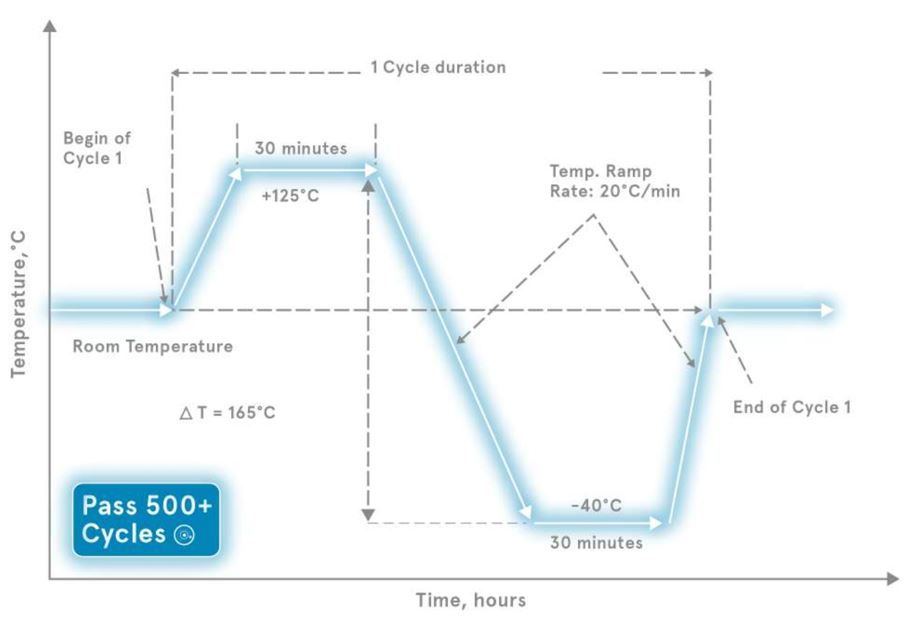

MINMAX’s modular power converters are rigorously tested for reliability, including over 500 temperature cycling tests simulating extreme conditions with temperature swings up to 165°C. Our designs use:

- High thermal conductivity adhesives and metal casings.

- Optimized PCB layouts for efficient heat dissipation.

Figure 5.1- Optimized thermal structure design that provides a wider operating temperature range and wider applications

Figure 5.2- Ensuring product reliability and durability through over 500 temperature cycle tests (TCT)

-

Cost-Effective Solutions

MINMAX’s modular power converters meet international safety standards, eliminating additional certification costs. By choosing modular converters, companies can:

- Avoid the expense of developing in-house solutions.

- Focus on core R&D while benefiting from reliable, pre-tested power modules.

Summary

| Design | Modular power supply | Discrete power supply |

|---|---|---|

| Save costs for more benefits | High | Low |

| Saved PCB space | More | Low |

| Fast upgrade compatibility | High | Low |

| Optimization of thermal performance design | Good | Poor |

| Operating environment temperature range | Wider | Narrow |

| Overall design considerations |

Good |

Poor |

| Overall electrical performance |

Good |

Poor |

Thank you for watching.

If you are interested in exploring other topics → Why Are Isolated DC-DC Converters Essential? A Comprehensive Guide

For more Technical Articles>>>

To learn more, please click on the following link:

【MINMAX Industrial Power Solution】

【MINMAX Railway Power Solution】

【MINMAX High Isolation and Voltage Resistant Power Supply Solution】

【MINMAX Medical Power Solution】